CNC Router

We have 2 big CNC routers. You need to schedule a class to get trained and signed off on them.

4' x 4' CNC router running LinuxCNC(EMC2)

Smaller router

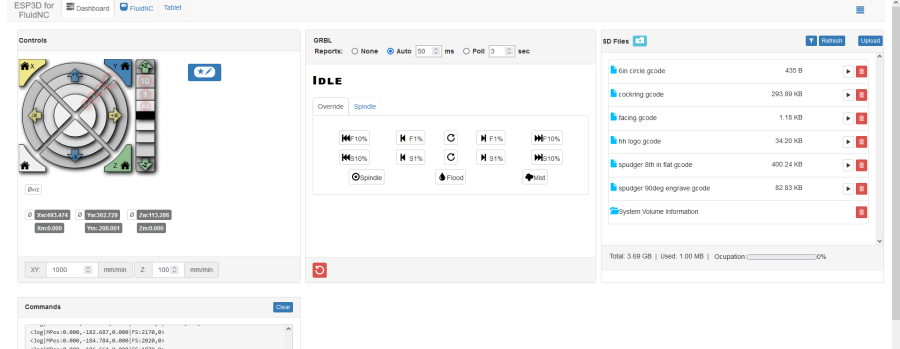

This machine runs [| FluidNC]. Reading this document does not clear you to run the machine. Please schedule a training on the Discord. Here is the power switch for the controller at the time of writing

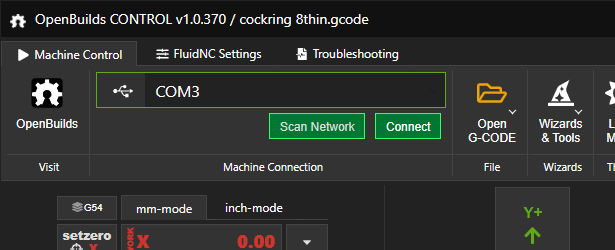

It's recommended you use [| Openbuilds CONTROL]. To connect, you can use a micro-usb and plug into COM directly, OR connect to the FluidNC hotspot with password 12345678. In Openbuilds CONTROL, click Scan Network

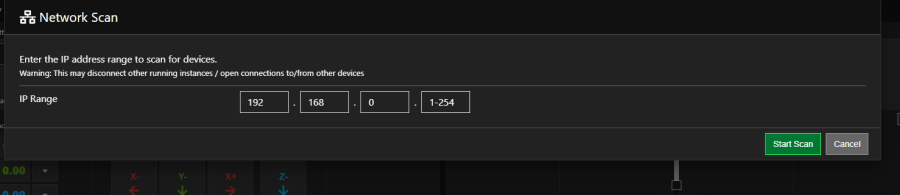

Make sure the IP range looks like this with 192.168.0.1-254

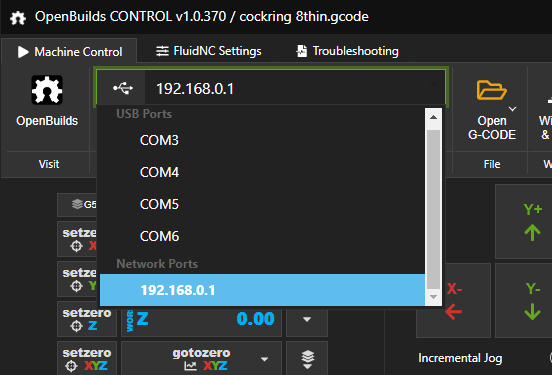

Then the device should show up in the list. Click connect.

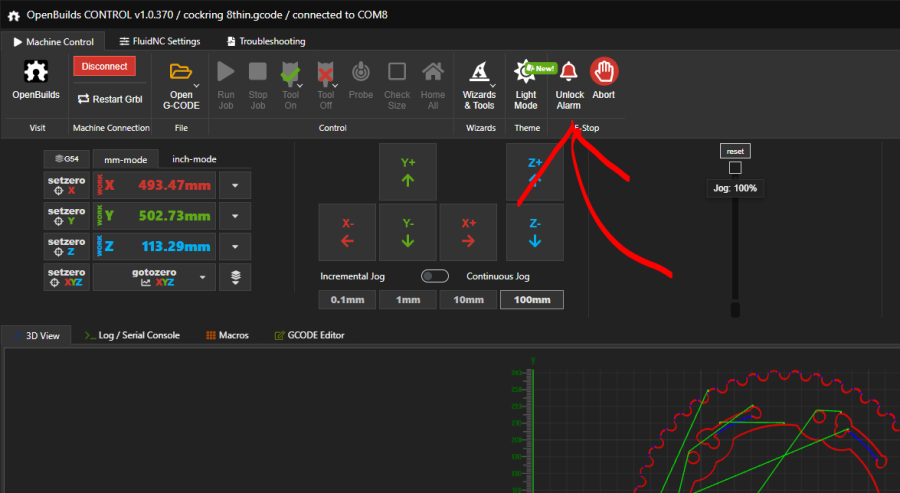

The first thing you probably have to do is clear the alarm that's on at startup

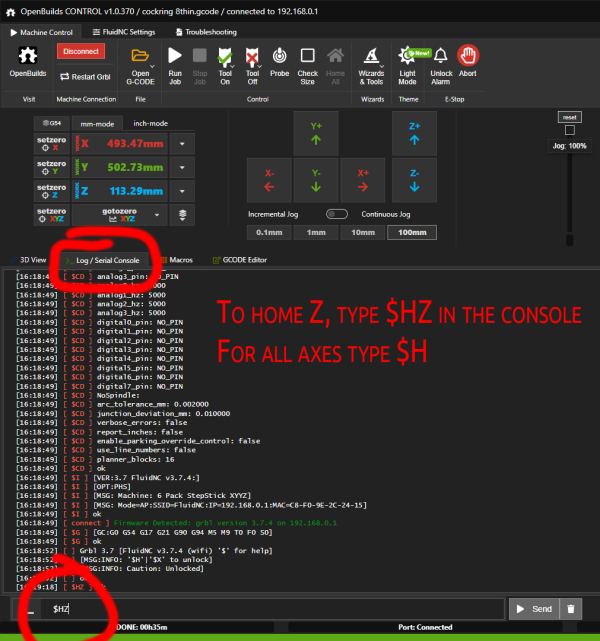

At the time of writing, CONTROL automatically disables homing due to a bug. There's probably a configuration change that could fix this. You can manually home with $H or $HZ if you only want to home the Z axis for example

Jog and touch off as you normally would. Once you're ready to run the machine, make sure the coolant is flowing and not leaking

To use the spindle, turn the power switch on, hold the green button for a couple seconds, and adjust the knob to set your RPMs. At 400hz, the spindle spins at 24,000rpm, so if you wanted 18,000rpm, you would set the knob to 300hz. 300hz is a good number for most things. The controller is has a module for connecting to the spindle and setting its speed electronically, but that hasn't been set up at the time of writing.

While the machine is running, make sure the fan is spinning on the controller and that it's not been knocked out of place. Also make sure the cables and hose aren't catching on anything. If you're spraying coolant on your part, be careful not to get it on the wood in places where it's been milled flat or else they'll warp.